Digitize, visualize, and synchronize material flow across your supply chain.

Eliminate material shortages and overstock with smart, digital replenishment.

SCY E-Kanban replaces manual card systems with real-time, sensor-driven replenishment signals — enabling seamless flow between suppliers, production lines, and warehouses.

Accelerate response times, cut material waste, and achieve true just-in-time efficiency.

Problem Statement

Manual Kanban systems often break down due to paper-based tracking, human error, or delays in replenishment. The result? Stockouts on the shop floor, excess inventory in stores, and reduced production throughput.

Impact: In discrete manufacturing, 70% of downtime is caused by missing parts or poor material visibility.

Solution Overview

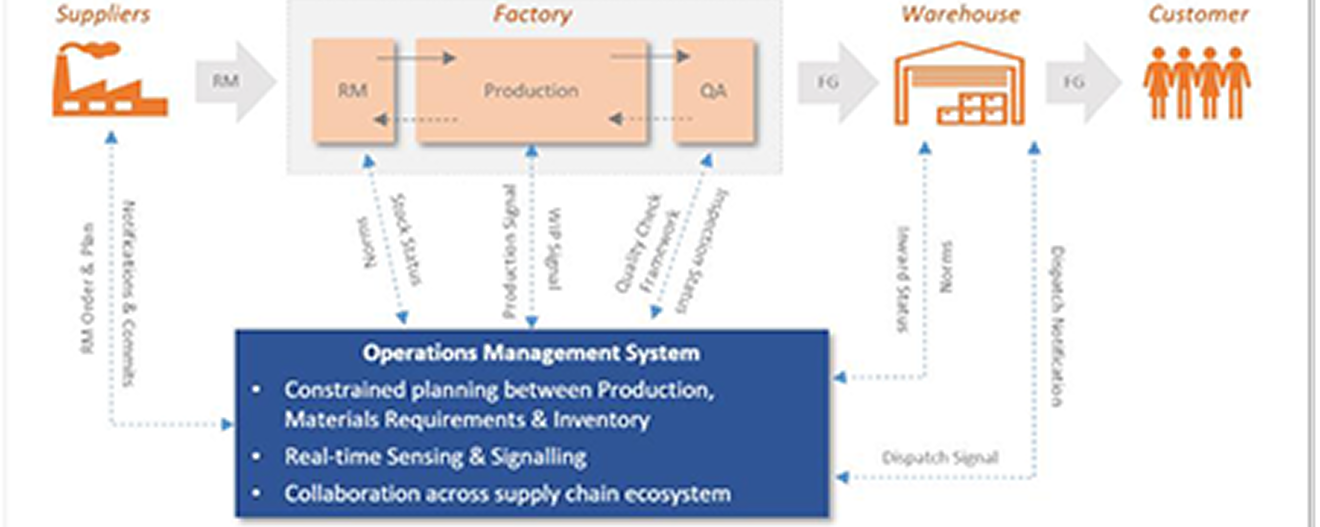

SCY E-Kanban digitizes the entire Kanban process — from signal generation to supplier communication — through IoT, barcode/RFID integration, and automated triggers.

It ensures every replenishment request is visible, traceable, and actionable in real time.

By synchronizing material movement with production schedules, SCY E-Kanban eliminates the chaos of manual tracking, reduces WIP, and increases overall equipment effectiveness (OEE).

Unlike static systems, it adapts dynamically to consumption rates, demand fluctuations, and priority changes — ensuring uninterrupted production flow.

Key Features & Capabilities

- Real-Time Digital Kanban

- Replace paper cards with live, automated replenishment triggers.

- IoT and Barcode/RFID Integration

- Connect bins, racks, and stations for hands-free signal generation.

- Dynamic Buffer Management

- Auto-adjust Kanban quantities based on actual demand and lead times.

- Supplier Collaboration Portal

- Share real-time signals with suppliers for synchronized replenishment.

- Analytics Dashboard

- Visualize material flow, lead times, and bottlenecks with actionable insights.

- ERP Integration

- Seamlessly connects with SAP, Oracle, and other ERP systems for end-to-end visibility.

Business Impact

- Eliminate material shortages and line stoppages.

- Reduce WIP and inventory levels by up to 25%.

- Shorten replenishment cycles and improve OEE.

- Enhance supplier responsiveness and accountability.

- Enable real-time visibility across production and supply lines.

Use Cases

- Automotive: Synchronize parts supply to assembly lines.

- Electronics: Manage high-mix, low-volume component flow.

- Aerospace: Improve traceability and reduce manual material handling.

- Industrial Manufacturing: Connect supplier and production Kanbans for uninterrupted flow.

Integrations & Compatibility

- ERP & Planning Systems (SAP, Oracle, Microsoft Dynamics)

- Transportation & Execution Platforms

- APIs & File-Based Integrations

- Cloud & On-Premise Deployments (Azure, AWS, Private Cloud)

Automotive Tier-1 Supplier – From Chaos to Flow

A Tier-1 auto parts supplier relied on manual Kanban cards and Excel tracking for replenishment. Frequent part shortages caused production delays and emergency shipments.

After implementing SCY E-Kanban, the system connected 14 production lines and 30 suppliers through digital signals.

RFID-based bins triggered replenishment in real-time, reducing WIP by 28% and improving production uptime by 15%.

With visibility dashboards, planners could anticipate shortages and proactively manage supplier lead times.