SCY Production Scheduling

Turn complex production plans into agile, optimized, on-time performance.

Schedule smarter. Produce faster. Deliver on time- every time.

SCY Production Scheduling helps manufacturers optimize production sequences, resource utilization, and changeovers with intelligent, real-time scheduling.

Plan faster, adapt instantly, and ensure smooth operations across your entire shop floor. Problem Statement

Manufacturers often face conflicting priorities — limited resources, frequent order changes, and unpredictable material availability.

Manual or spreadsheet-based scheduling leads to idle resources, costly changeovers, and missed delivery dates.

Impact: Over 60% of manufacturing delays stem from poor schedule synchronization and lack of real-time visibility. Solution Overview

SCY Production Scheduling transforms the way you plan and execute manufacturing operations.

It optimizes production sequences and resource allocation using advanced solvers, integrating real-time data from ERP, MES, and shop-floor systems.

The result: reduced setup time, maximized throughput, and dependable delivery performance — all through a single, intuitive interface.

Unlike rigid scheduling systems, SCY’s no-code flexibility and advanced solvers (MILP, heuristics, and metaheuristics) allow planners to respond rapidly to changes, making scheduling not just faster, but smarter. Key Features & Capabilities

- Sequence-Dependent Optimization

- Minimize changeovers and downtime through intelligent campaign grouping and machine sequencing.

- Real-Time Resource Loading

- Allocate workloads dynamically across alternate machines, routings, or materials.

- Advanced Optimization Solvers

- Leverage MILP and heuristic algorithms for complex, constraint-based scheduling.

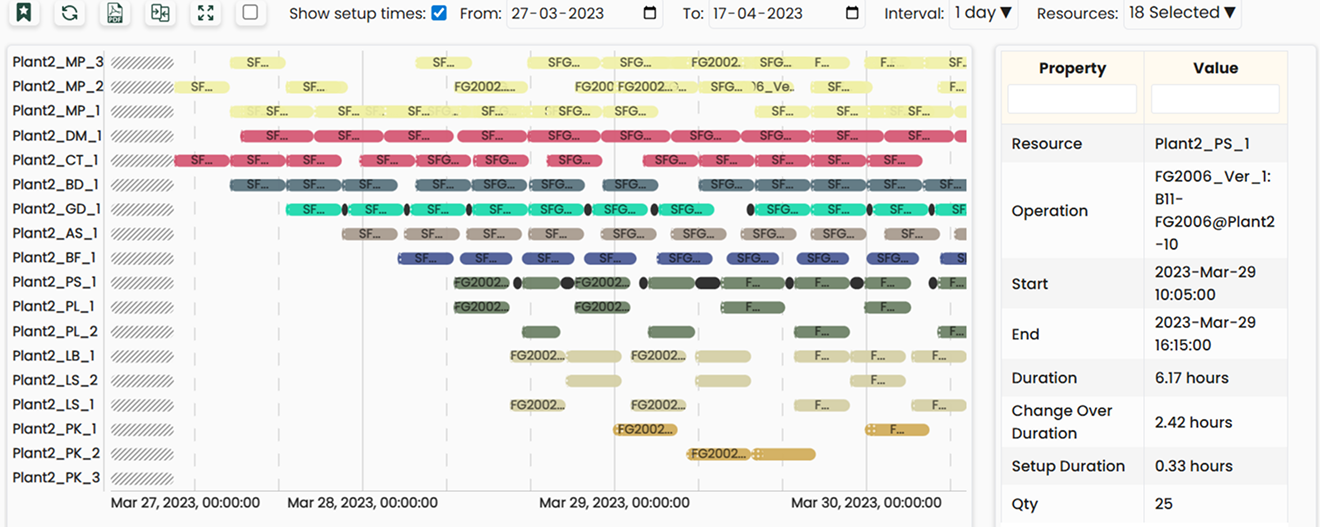

- Interactive Gantt & Visual Planning

- Drag-and-drop Gantt views with color-coded insights for planners and supervisors.

- Scenario Simulation & What-If Analysis

- Compare multiple scheduling options quickly to select the best-performing plan.

- Flexible Deployment & No-Code Setup

- Configure rules and workflows easily — deploy on cloud or on-premise as needed.

Benefits / Business Impact

- Increase resource utilization by 10–25%.

- Reduce setup and changeover losses by up to 20%.

- Improve OTIF (On-Time, In-Full) performance.

- Lower WIP and finished goods inventory.

- Accelerate planning cycles — from hours to minutes.

Use Cases / Applications

- Automotive: Balance assembly line workloads and minimize tool changeovers.

- FMCG & Food: Manage campaign-based production and perishability constraints.

- Pharma & Chemicals: Schedule by batch attributes and regulatory priorities.

- Electronics & Industrial Equipment: Optimize multi-stage, resource-intensive production environments.

Integrations / Compatibility

- ERP Systems: SAP, Oracle, Microsoft Dynamics

- MES / Shop-Floor Systems: Real-time data synchronization

- Data & Visualization: Power BI, Tableau

- Deployment Options: Cloud, On-premise, or hybrid

European Ice Cream Manufacturer – From Chaos to Churn Control

A leading European ice cream maker faced inefficiencies in campaign planning and machine sequencing across multiple plants. Long setup times, poor batch-size balancing, and manual rescheduling impacted production throughput and delivery reliability.

By deploying SCY Production Scheduling, the company used intelligent solvers to optimize flavor sequencing and freezer line utilization. Gantt-based visualization provided planners with immediate visibility into constraints and opportunities. Within three months, setup losses dropped by 20%, finished goods inventory by 15%, and OTIF rates improved significantly — achieving both seasonal flexibility and operational consistency.